Diesel Generators for Load Management Ensuring Reliable Power Supply in Critical Situations

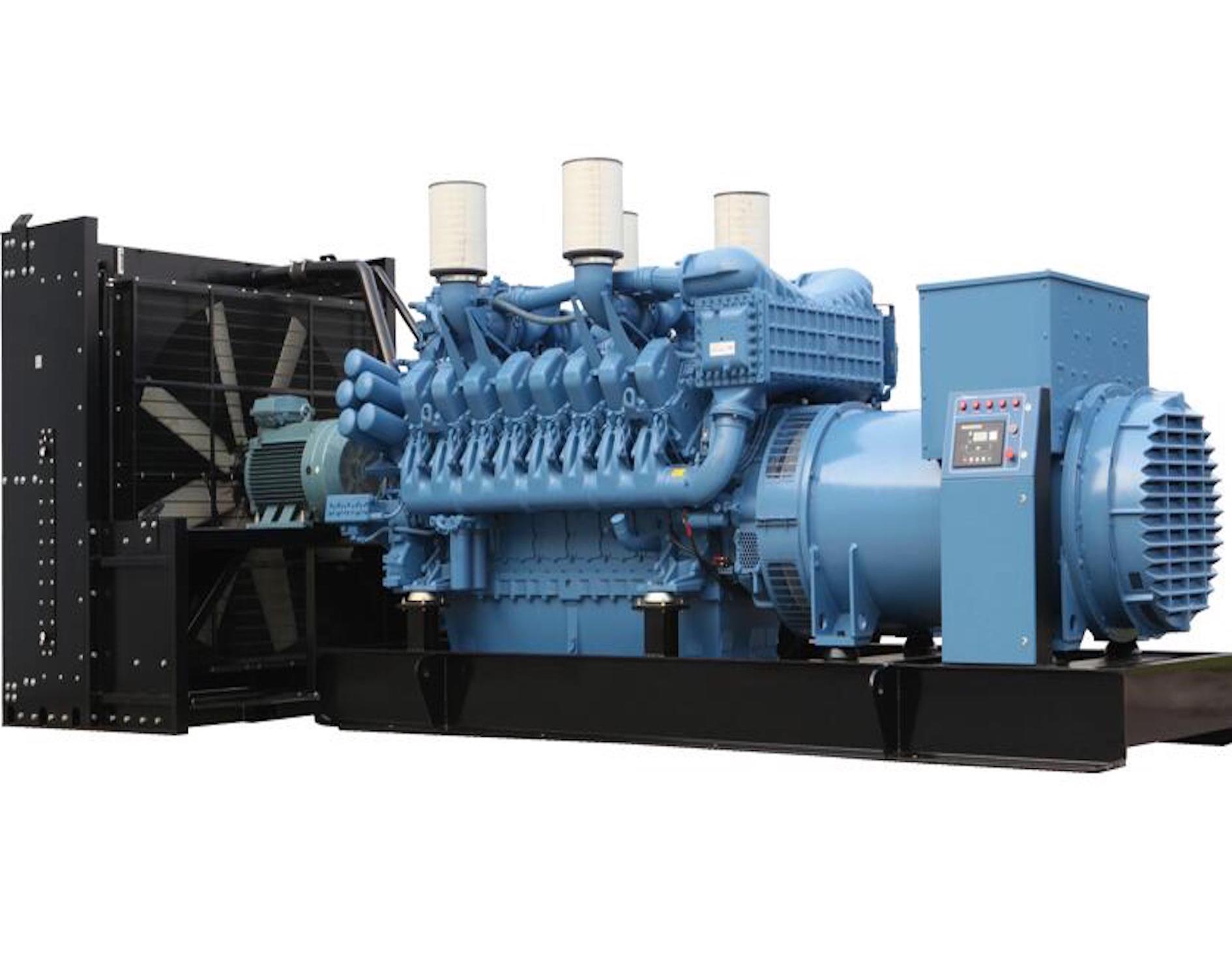

Introduction: In today's fast-paced world, uninterrupted power supply is vital for various industries and sectors. From hospitals and data centers to manufacturing plants and construction sites, a reliable source of electricity is essential to keep operations running smoothly. However, power outages and fluctuations are inevitable, and they can lead to significant financial losses and operational disruptions. To mitigate these risks, many businesses and organizations rely on diesel generators for load management. https://www.lkpowerplant.com/product/robust-240kva-power-solution-diesel-generator-set-for-commercial-projects/ explores the importance of diesel generators, their working principle, and their role in ensuring uninterrupted power supply. 1. Understanding Load Management: Load management refers to the process of balancing the power demand and supply to prevent overloading and voltage fluctuations. It involves monitoring the power requirements of different electrical devices and distributing the load across multiple sources effectively. Load management is particularly crucial in situations where the power demand exceeds the capacity of the primary power source or during emergencies when the main grid fails. 2. Diesel Generators: A Reliable Power Source: Diesel generators have long been recognized as a dependable and cost-effective solution for backup and prime power applications. These generators are designed to convert mechanical energy into electrical energy using the principle of electromagnetic induction. They consist of an internal combustion engine that runs on diesel fuel and an alternator that converts the mechanical energy from the engine into electrical energy. 3. Working Principle of Diesel Generators: The operation of a diesel generator involves multiple components working together seamlessly. The primary components include the engine, fuel system, alternator, control panel, and exhaust system. The engine burns diesel fuel, producing mechanical energy that drives the alternator. The alternator, also known as the generator head, consists of a rotating magnetic field and a stationary coil. As the engine rotates the magnetic field, it induces an alternating current (AC) in the coil, which is then converted to usable electricity through a process called rectification. 4. Advantages of Diesel Generators for Load Management: 4.1. Robust and Reliable: Diesel generators are known for their durability and reliability. Unlike other types of generators, they can operate continuously for extended periods, making them ideal for critical applications. The robust design of diesel engines ensures their ability to withstand heavy loads and harsh operating conditions, making them suitable for industries that require a constant and uninterrupted power supply. 4.2. High Power Output: Diesel generators are capable of producing high power outputs, making them suitable for both small and large-scale applications. They are available in various sizes and capacities to meet the specific power requirements of different industries. Moreover, diesel generators can efficiently handle sudden load fluctuations without compromising their performance, ensuring a stable power supply to critical equipment and systems. 4.3. Fuel Efficiency: Diesel generators are known for their fuel efficiency compared to other types of generators. This is primarily due to the higher energy density of diesel fuel, which allows diesel engines to extract more energy from a given volume of fuel. Additionally, diesel engines are designed to run at a constant speed, resulting in optimized fuel consumption and reduced operational costs. 4.4. Easy Maintenance and Availability of Fuel: Another advantage of diesel generators is their ease of maintenance. Diesel engines have fewer moving parts compared to gasoline engines, reducing the risk of mechanical failure. Moreover, diesel fuel is widely available, making it easier to source and store in large quantities. This availability ensures a continuous fuel supply, even during emergencies or natural disasters. 4.5. Quick Start and Load Response: Diesel generators have a quick start-up time, allowing them to provide power within seconds of an outage. This feature is crucial for applications where any downtime can lead to significant financial losses or compromise safety. Additionally, diesel generators can quickly respond to sudden load changes, ensuring a stable power supply even during peak demand periods. 5. Applications of Diesel Generators in Load Management: 5.1. Backup Power for Critical Facilities: Critical facilities, such as hospitals, data centers, and telecommunication networks, rely on diesel generators as a backup power source. These generators ensure uninterrupted power supply during grid failures or scheduled maintenance, preventing potential risks to human life, data loss, and communication disruptions. 5.2. Construction and Mining Sites: Construction and mining sites often operate in remote locations with limited access to the main grid. Diesel generators provide a reliable power source in these challenging environments, enabling the operation of heavy machinery, lighting systems, and other essential equipment. 5.3. Manufacturing and Industrial Applications: Manufacturing plants and industrial facilities require a consistent power supply to maintain production schedules and prevent costly downtime. Diesel generators offer a reliable and efficient solution for load management in these sectors, ensuring uninterrupted power supply for critical machinery, HVAC systems, and lighting. 5.4. Event Management and Entertainment: Diesel generators are commonly used in event management, outdoor festivals, and entertainment industries, where temporary power supply is required. These generators can meet the high power demands of stages, lighting systems, sound equipment, and other event-related components. 6. Environmental Considerations: While diesel generators offer numerous benefits for load management, it is essential to address their environmental impact. Diesel engines produce emissions, including particulate matter (PM), nitrogen oxides (NOx), and carbon dioxide (CO2). To mitigate these emissions, modern diesel generators are equipped with advanced emission control technologies, such as diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems. Additionally, the use of biofuels and alternative fuels can further reduce the carbon footprint associated with diesel generators. Conclusion: In conclusion, diesel generators play a crucial role in load management, ensuring uninterrupted power supply in critical situations. Their robustness, high power output, fuel efficiency, and quick response to load changes make them an ideal choice for various industries and sectors. However, it is important to consider the environmental impact of diesel generators and adopt measures to minimize emissions. With proper maintenance and responsible usage, diesel generators can continue to serve as a reliable power source, safeguarding essential operations and critical infrastructure against power disruptions.